Technical Data Sheet Piezotech RT ®

source:未知date:2018/12/15 18:52 browse:

General Properties

Piezotech RT TM is a unique range of printable Fluorinated Electroactive Polymer with Relaxor ferroelectric properties.

Dielectric:

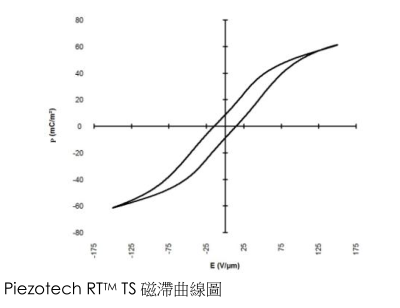

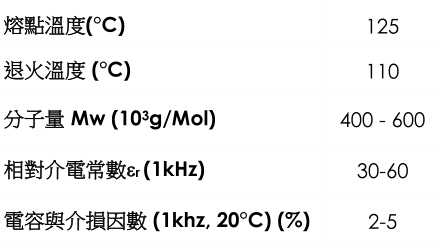

Piezotech RT TM have high dielectric constant (upto 60) , high dielectric strength (>350V/µm), high induced polarization and low remnant polarization.

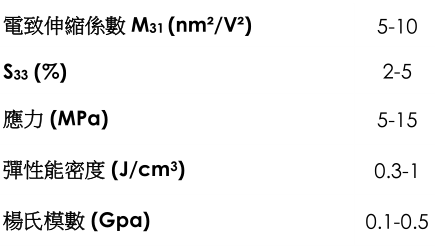

Electromechanical properties

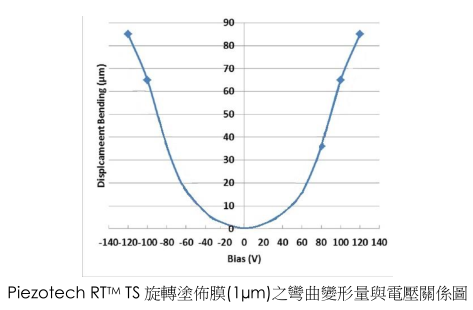

Piezotech RT TM have high electrostrictive properties. Films based on these polymers can exhibit electromechanical deformation above 5% combined with high elastic modulus (up to 300MPa) and high breakdown voltage. These materials are suited for the development of thin,light and flexible actuators.

Applications haptic devices, microfluidics, speakers, energy storage, high-k dielectrics for transistors, electrocaloric...

Piezotech RT TM Typical Properties

Processing

Solubilization & Filtration

Piezotech RT are soluble in ketone solvents (Methyl Ethyl Ketone (MEK), Methyl Isobutyl Ketone(MIBK), cyclo-hexanone, cylopentanone etc…), Dimethyl formamide (DMF), Dimethyl Sulfoxide (DMSO), Phosphate solvents (Triethyl phosphate) etc… In order to get homogeneous films with high electrical breakdown a filtering step of the solution is required, it will remove impurities and prevent gel formation.

Film Formation

Solution can be deposited via solvent cast, screen printing, spin-coating or other printingtechniques on a glass, silicon, Polyimide, PEN… substrate under clean atmosphere until anhomogeneous and dry film is formed.

Film annealing

Annealing is a critical step to provide film with the best properties, it will control crystallization of the material and enhance electrical as well as mechanical properties. Rapid annealing may be obtained on thin films using Infrared or Flash annealing.

Clean-up

The product can be cleaned up with ketones solvents (MEK (methyl ethyl ketone), Cyclopentanone …)